Workflow

This is the flow of operations after receiving an order from the customer.

Depending on the shape and material, the process from primary processing to quality inspection may vary.

1 Material management

Our company has stock materials ready to produce at least 100-minute range, enabling us to respond to short delivery times.

In addition, materials are controlled by lot to enable tracing defects in the event that they occur.

To compensate for product distortions and to increase machining accuracy, we often apply centerless machining.

2 Primary processing

We use CNC lathes and other machines that we have customized for Plastic processing. Our accumulated know-how and experience in Plastic cutting since the company’s foundation has enabled us to reduce losses and processing time.

3 Cleaning and drying

The oil and chips from the machining process are cleaned using an ultrasonic cleaner and then dried.

4 Secondary processing

Polishing, back surface machining and complex hole machining using tapping centers are carried out using different machining equipment to the primary machining. In addition, jigs and round bites can be made in-house, which makes it possible to carry out more efficient and delicate operations.

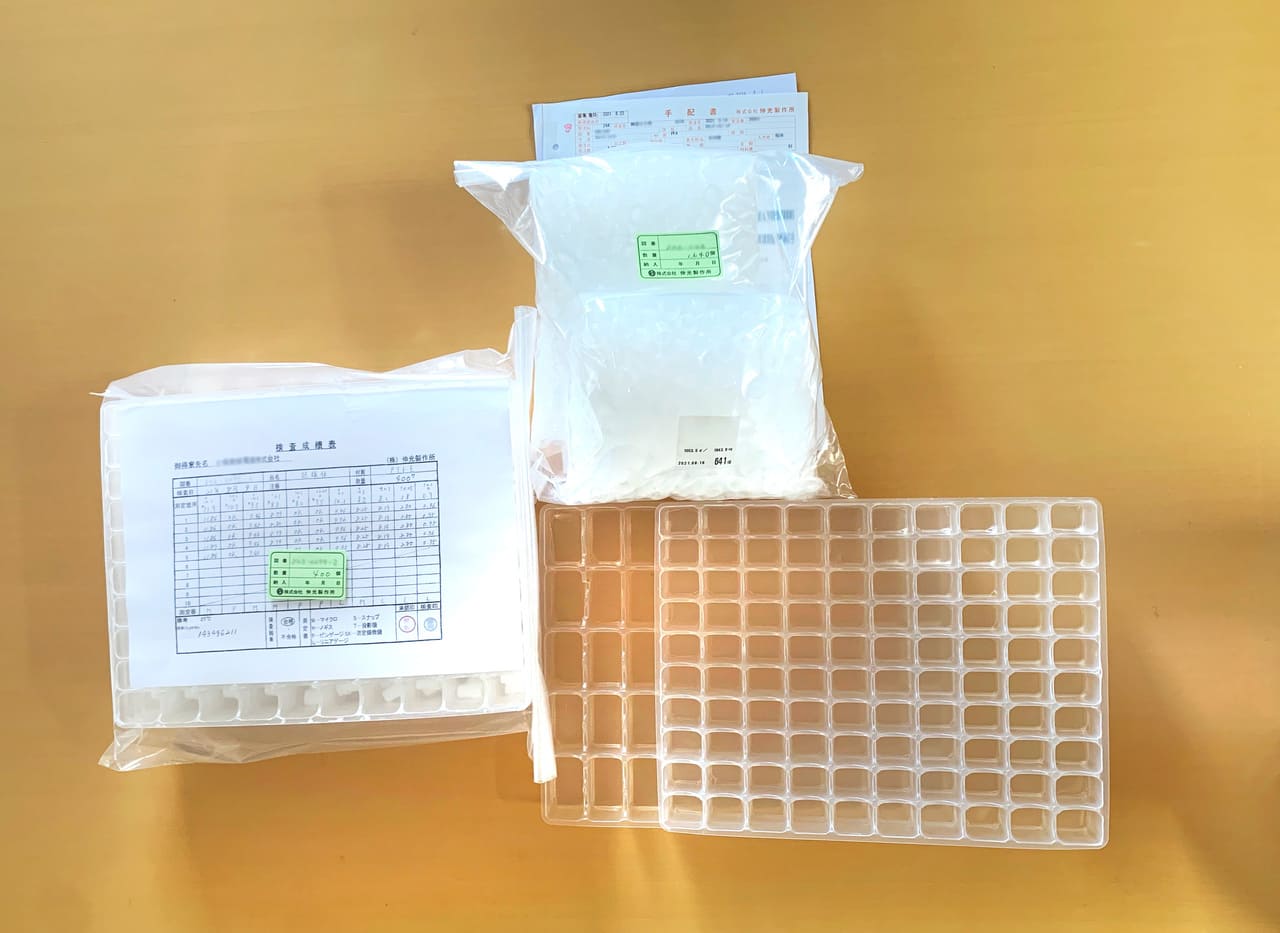

5 Quality inspection

In accordance with the agreements made with our customers, we carry out quality inspections using a variety of measuring instruments. The products are systematically controlled so that any defective products can be traced immediately.