For cutting, we can process a wide range of Plastic materials, generally referred to as synthetic resin (synthetic Plastic compound) or plastic.

However, the only materials that can be processed are bars and some plate materials (sheet materials). We do not handle pellets (grain shape), powders, or liquids.

If we can manufacture it, we will manufacture even one, so please do not hesitate to consult us.

※At our company, we will make from plastic rods and pipes by the “processing method of shaving and making holes”. This method is suitable for the production of 1 to 1000 pieces (or even 10000 pieces). In this range, the cost is almost always lower than for molding. It is also possible to achieve more “precise machining” than with molding.

※What is a molding processing?

“This is the process of pouring molten plastic into a metal mold”, often used for mass production.

We can process plastic materials (bars and plates) by cutting them with cutting tools (bites, drills, end mills, etc.). We are particularly good at machining from bar stock (materials that cannot be molded and precision processed).

If the shape or material cannot be processed by us, we can introduce the outsourced processing subcontractor.

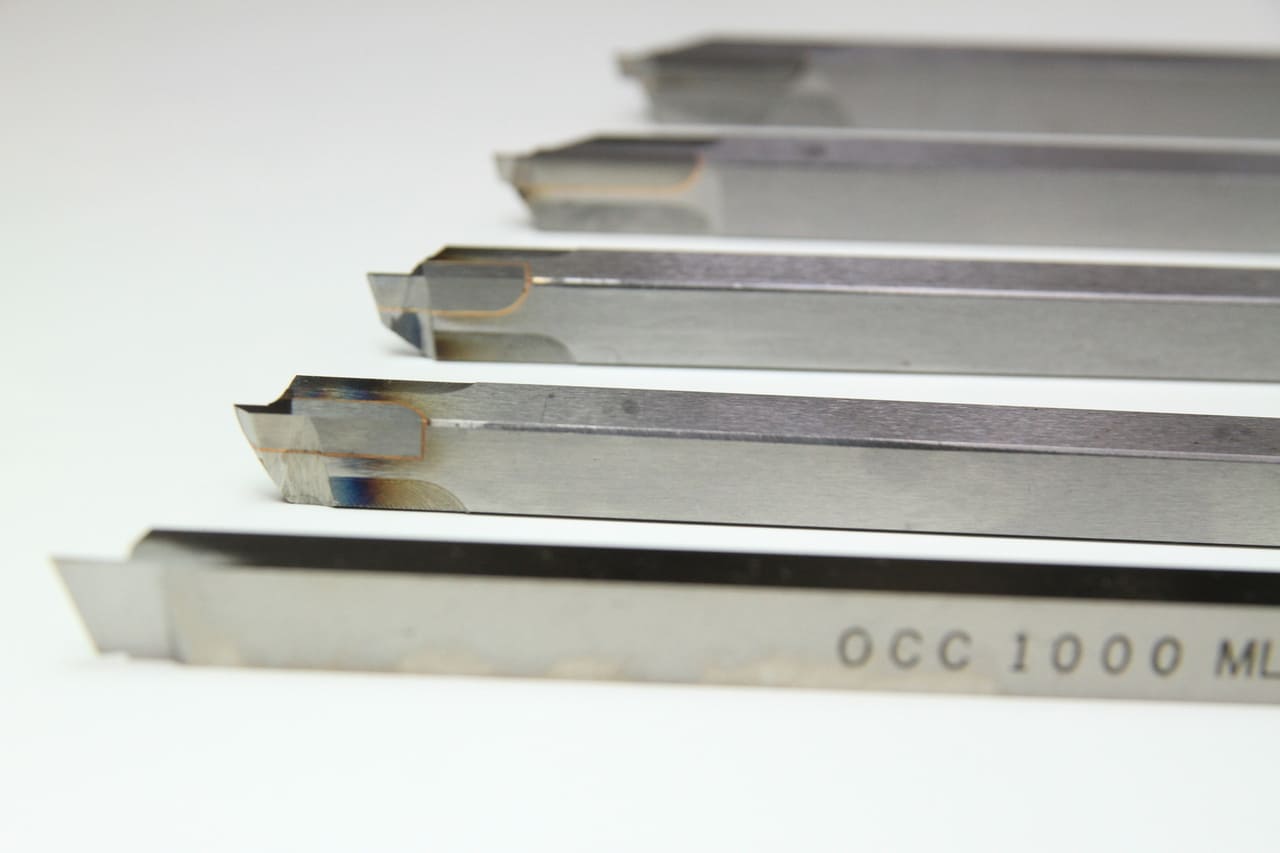

Cutting knives for NC lathes

We are able to produce a wide variety of products in small lots using the latest CNC lathes and CNC centers.

We can process from 1 to hundreds of thousands of pieces with an outside diameter of 12mm or less. We can process from one to several thousand pieces with an outer diameter of 40 mm or less.

Plastic is a difficult material to achieve accuracy, and even according to JIS standards, the accuracy range is wider than that of metal. When comparing plastic and metal, many metals are hard materials that make it easy to pursue high precision. Compared to this, it is extremely difficult to pursue high precision with plastic.

We cannot change the characteristics of the material itself, but we can use our experience and knowledge as a manufacturer specializing in plastic processing to achieve high precision in the range of 1/100mm in plastic. Please consult us on the design.

You can send us the drawing of the part, or our sales person will visit you for further information.

Basically, we can, but we will need to see the actual product.

We offer factory tours (at our Tokyo and Nasu factories) on request, so please feel free to visit our manufacturing sites. If you would like to visit our factories, please click here.

※Some parts cannot be shown due to regulations. Thank you in advance for your understanding.